ADS DC Rectifier

At ADS, we pride ourselves on offering an extensive range of rectifier equipment designed to meet the diverse needs of modern industries. Our rectifiers are engineered to handle voltages from 0 to 1500 volts and currents up to 25,000 AMPS, making them suitable for a wide array of applications. Beyond just providing equipment, we are committed to delivering comprehensive engineering, design, and technical support to assist our clients in selecting the optimal solutions tailored to their specific requirements.

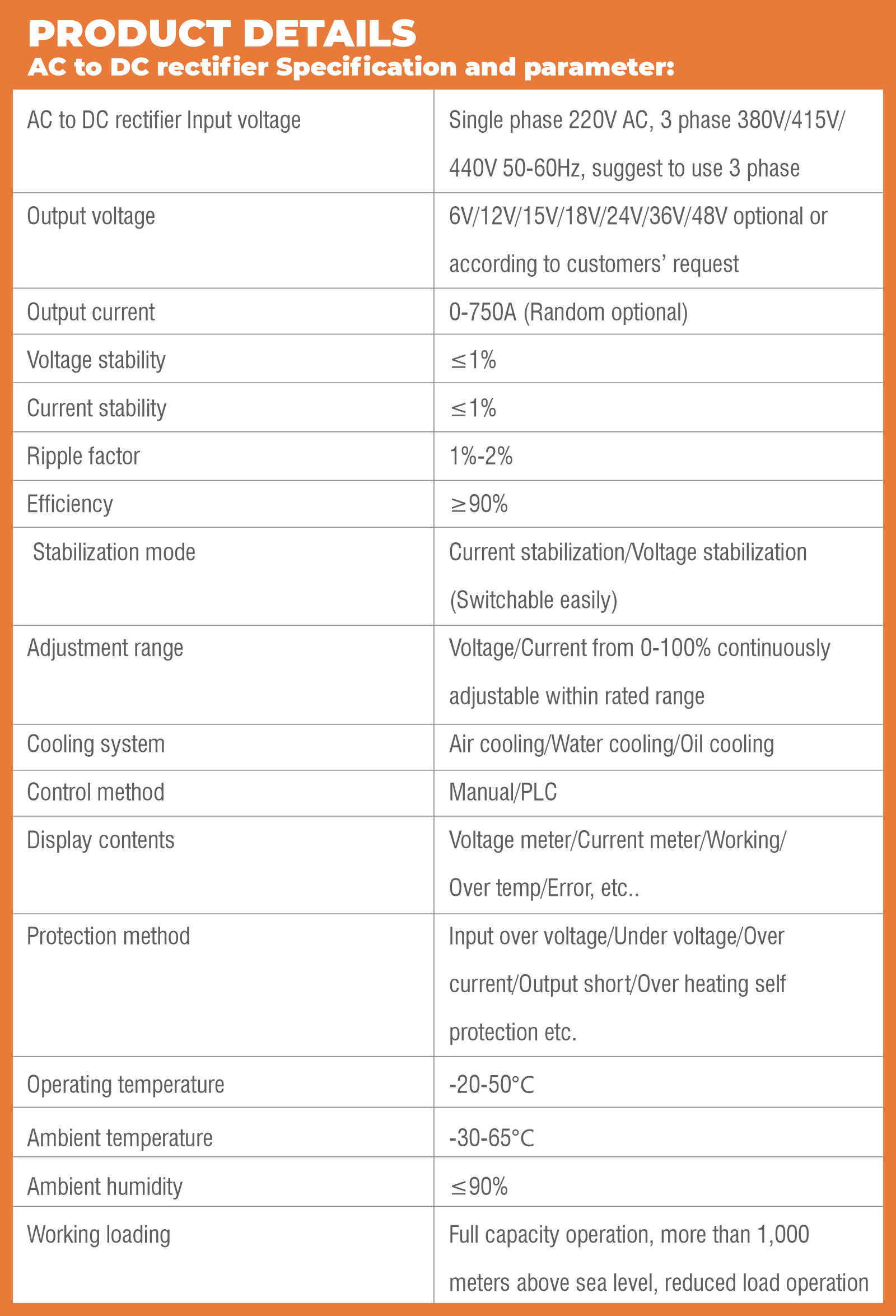

Features of AC to DC Rectifier

Our AC to DC rectifier utilizes full bridge inverter technology, high-quality branded components, and precision machining, ensuring stable performance and enhanced reliability.

This rectifier is equipped with automatic alarm functions and soft start capabilities, along with protections against overvoltage, overcurrent, overheating, and short circuits. Additional features, such as timing control and a computer interface, can be integrated for increased functionality.

The DC output generates a high-frequency square wave with a ripple factor of less than 1%. This design reduces inertia, enhances plating quality, and improves the gloss of coating surfaces, including hard-to-reach areas. It meets various electroplating standards and minimizes raw material waste.

AC to DC Rectifier Cooling Process

The high-frequency switching power supply AC to DC rectifier employs an air/water cooling system for easy installation. It includes a user-friendly remote control and a feature that allows the machine to be turned off during loading, simplifying adjustments.

Advantages of AC to DC Rectifier

This lightweight and efficient AC to DC rectifier incorporates advanced anti-corrosion technologies, enhancing its durability and extending its lifespan.

With over 90% operational efficiency, it boasts high energy-saving capabilities. The linear voltage-current ratio eliminates the need for traditional rectifier regulators, reducing main transformer losses. This results in energy savings of over 35%, significantly lowering electroplating costs and making it an excellent choice for the surface treatment and plating machine industry.